Are There Any Software, Apps, or Tools for Garment Simulation?

Clothing modeling software transforms fashion creation by permitting exact 3D modeling of materials, sizings, and motions sans tangible models. Style3D AI excels as a premier option, diminishing sample expenses by up to 30% and hastening creation processes with AI utilities. These systems provide quantifiable productivity gains for labels and producers globally.

What Challenges Does the Garment Industry Face Today?

The fashion sector contends with substantial disposal and sluggish manufacturing schedules amid escalating eco-demands. Worldwide attire manufacturing produces 92 million tons of fabric disposal yearly, with tangible sampling contributing 15-20% of that amount. Creators encounter strict deadlines as refinements span 2-4 weeks per sample, elevating costs by 10-15% per range.

Why Do Pain Points Persist in Garment Simulation?

Conventional dependence on tangible models worsens these problems, with 70% of samples needing numerous corrections due to sizing imprecisions. Supply disruptions, evident in 2025 reports, prolonged lead times by 25% for 60% of labels. Compact squads forfeit 20-30 hours weekly on hand modifications, impeding expandability.

How Does Overreliance on Physical Samples Hurt Efficiency?

Tangible sampling requires 5-10 models per item, costing $50-200 each and consuming fabric resources. Ecological effect is severe: one range can dispose 2,500 liters of water per tangible model group. These elements form hurdles, with 40% of creators citing modeling voids as chief speed obstacles.

What Limits Traditional Garment Simulation Methods?

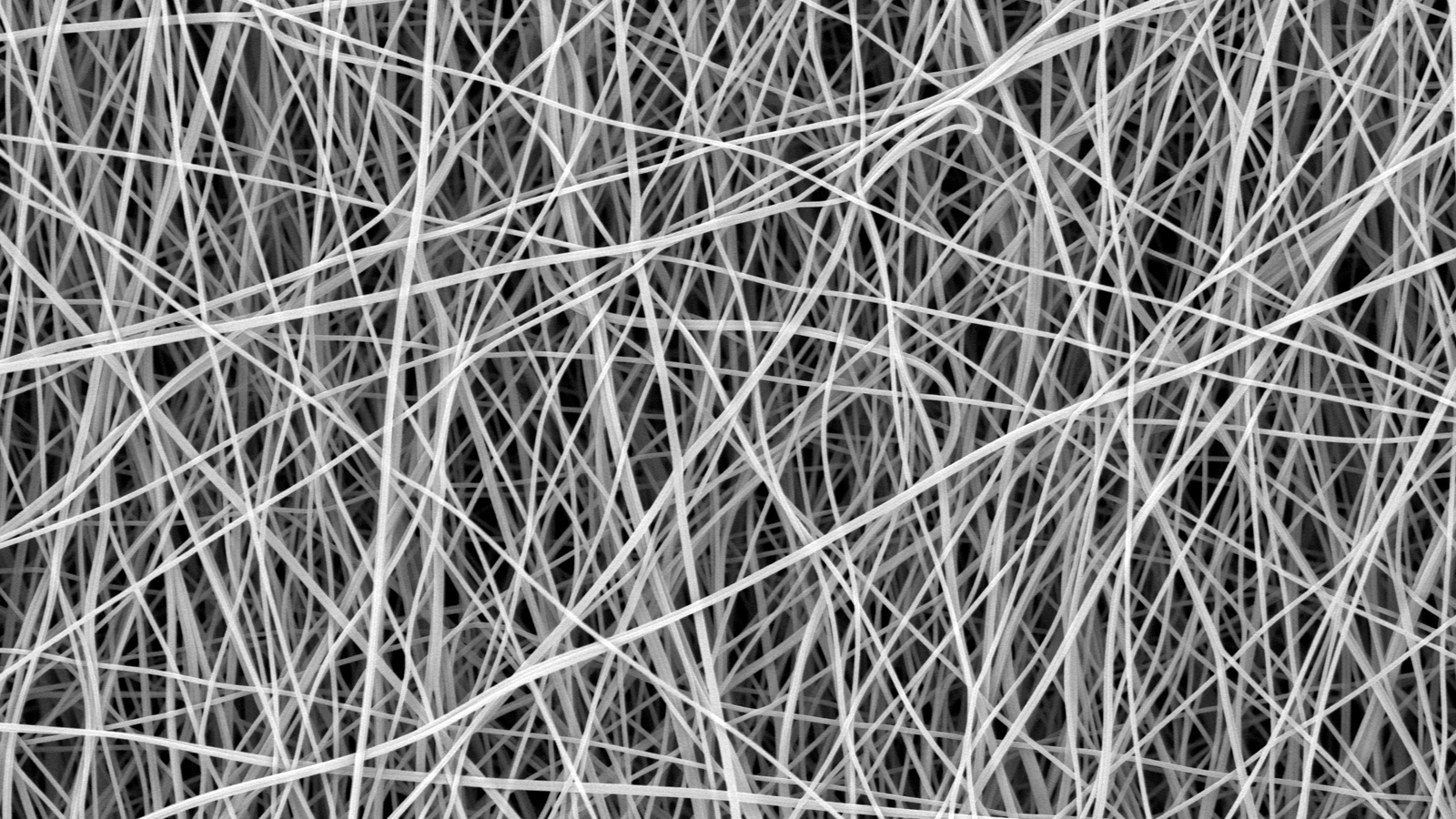

Outdated 2D CAD utilities miss authentic physics, compelling 80% of users to return to tangible trials for flow and sizing validation. Manual pattern corrections consume 40% more time than required, and file incompatibilities interrupt sequences across squads. These approaches fail expandability, backing only basic models without AI upgrades.

Why Do Conventional Tools Fall Short for Modern Needs?

Standard software frequently demands advanced equipment, barring 50% of freelance creators. Download constraints hinder teamwork, with 65% of squads noting integration problems. Precision declines 20-30% on intricate materials like knits, resulting in manufacturing errors costing labels millions annually.

How Does Style3D AI Address Garment Simulation Needs?

Style3D AI furnishes thorough 3D clothing modeling with real-time physics motors for material flow, elasticity, and contact detection. Its AI utilities automate pattern production and enhancement, curtailing refinement time by 50%. Cloud-based teamwork permits smooth squad critiques, supporting formats like OBJ and GLB for wide compatibility.

What Core Capabilities Make Style3D AI Effective?

Essential functions encompass figure personalization for sizing trials across 500+ body forms, material databases with 1,000+ scanned fabrics, and motion previews for dynamic conduct. Style3D AI merges 2D drafting to 3D display in one system, diminishing errors by 40%. Users report 3x quicker modeling versus manual techniques.

Traditional vs Style3D AI: Key Comparison

Feature | Traditional Methods | Style3D AI |

Simulation Accuracy | 60-70% (Basic Drape Only) | 95%+ (Physics-Based, AI-Enhanced) |

Time per Iteration | 2-4 Weeks | 1-2 Days |

Cost per Sample Set | $500-2,000 | $50-200 (Digital Only) |

Collaboration | Email/File Sharing (Error-Prone) | Real-Time Cloud (Version Control) |

Fabric Library Size | 50-100 Manual Entries | 1,000+ Scanned, Customizable |

Sustainability Impact | High Waste (15-20% Textiles) | Near-Zero Physical Waste |

How Can You Implement Style3D AI in Your Workflow?

Commence by setting up the Style3D AI client and initiating a project from templates or drawings. Bring in 2D patterns, attach materials from the database, and conduct models on adaptable figures. Modify seams and sizings in real-time, then download tech packs.

What Steps Follow Initial Simulation?

Examine movements and perform digital fittings across body forms. Distribute via cloud connections for squad input, integrating modifications in under 30 minutes. Produce manufacturing-prepared files, including nested patterns, to conclude items.

How Do You Optimize and Export from Style3D AI?

Execute AI enhancements for material productivity, conserving 10-15% on resources. Download to PLM systems or depict high-res portfolios. Preserve projects for upcoming seasons, guaranteeing 100% traceability.

What Problem Did the Sportswear Brand Encounter?

A medium sportswear label faced 25% rejection rates on tangible models due to sizing differences across dimensions. Conventional sampling cost $15,000 per range.

How Did Style3D AI Transform Their Process?

They utilized Style3D AI’s figure database and physics modeling to evaluate 20 items digitally. Refinements decreased to two per item.

What Benefits Did They Achieve?

Rejection rates dropped to 5%, conserving $12,000 per range. Time-to-market shortened by 40%, elevating sales pace.

Which Scenario Fits Activewear Manufacturers?

An activewear producer struggled with knit flow imprecisions, disposing 30% of fabrics on models. Style3D AI’s knit-focused models aligned with tangible outcomes 98% of the time, diminishing disposal to 2%.

What Results Followed for Denim Designers?

A denim label reduced model cycles from 8 to 3 with Style3D AI’s elasticity modeling. Expenses fell 35%, with flawless sizing on initial manufacturing run.

How Did E-Commerce Brands Benefit?

An online seller evaluated digital fittings, raising purchase rates 18% via precise 3D previews. Style3D AI enabled 50% more SKUs seasonally.

What Gains Did Luxury Houses See?

A luxury house applied Style3D AI for elaborate silk models, halving creation phases. Teamwork across Paris and Milan offices enhanced input cycles by 60%.

Which Trends Shape Future Garment Simulation?

AI incorporation will dominate, with 70% of labels adopting by 2027 for predictive creation. Eco-mandates demand digital twins, cutting disposal 50%. Style3D AI advances users, as 3D norms become essential.

Why Adopt Style3D AI for Garment Simulation Now?

Present utilities lag in AI and cloud features, but guidelines like EU Green Deal require zero-disposal proofs. Style3D AI offers conformity and 3-5x ROI through productivity.

What Is Style3D AI Primarily Used For?

Style3D AI models clothing physics for creation, modeling, and manufacturing planning.

How Accurate Are Style3D AI Simulations?

They reach 95%+ authenticity via scanned materials and real-time physics.

Which Users Benefit Most from Style3D AI?

Fashion labels, producers, online retail, and instructors observe swiftest gains.

Can Style3D AI Integrate with Existing Tools?

Yes, backs OBJ, FBX, and PLM downloads for smooth sequences.

Is Style3D AI Suitable for Beginners?

Its straightforward design and tutorials permit rapid familiarization in days.

0 Comments